Hey there

@mikefamig

My long automotive service career includes 32 years a licensed State of California Smog Check Inspector and Technician, so I have extensive emissions experience, including providing official state-sponsored training to existing licensed technicians on catalytic converter performance. Needless to say, I've dealt with a lot of catalyst issues over the years.

Frankly, I've seen very limited success with liquid voodoo cat refreshers. Many guarantees, but the fine print always puts the onus on you to prove your engine is in a good level of tune and running good, +/- 2% stoichiometric fuel control (14.7:1 air/fuel ratio). Such precise fuel control is necessary for a catalyst to convert bad gasses to inert, and there is not much that any juice can do to improve that cat's efficiency if fuel control is not spot-on.

However, if the additive is effective in helping clean the injectors and maybe even remove carbon deposits that were hindering intake air/fuel flow, and this brought fuel control back into the happy zone, the secondary effect of that might be that the catalyst is now able to do it's job better and reduce tailpipe emissions more effectively. So there's that, but it's not the juice bringing the cat around; it's the better running.

Far as "cleaning" the cat goes, you might have a real good running engine in ideal fuel control, but it's also burning a lot of oil, say worn valve guide seals (think 70s-80s Chevy 305, or every ford V8 same era that isn't called 302 or 5.0) That wet oil in the exhaust can and will contaminate the cat. First it will reduce cat temps and render the conversion process useless as they need to be hot to function. But they will still get hot enough to scorch that oil to an internal, baked on coating. The only way to "clean" that up is extreme heat. Frankly, the additives won't do that.

What will though is a misfire. I've dealt with many such scenarios where an oil-baked cat caused high emissions and inspection failures. First off, I don't want to fail my customers, and secondly, I don't want all that oil content drawn into my analyzer. Often times I will "precondition" the cat by running the engine at 2500 RPM for an extended period, say ten minutes to see if it will get hot enough on it's own to burn off the oil. If still a little skanky, I'll spray about a 5 second, regulated blast of carburetor cleaner into a vacuum hose at 2500 RPM 6-8 times over a 3-4 minute period. This creates controlled misfiring that dumps raw fuel into the cats, which ignites upon entry, super-heating that cat and cooking that oil film right out of there. Another 3 minutes at 2500 RPM to regain fuel control and settle that cat back down and you have VERY clean tailpipe emissions levels within that sweet smell of conversion.

I'd venture to say your driveability improvements are the biggest contributor to your performance gains, and even your tailpipe hiss. But not through opening up restricted cats. Nothing will do that except a big pry bar and hammer to gut it out. But with these older EFI Ford mills, air injection can cause that bummer noise. And a poor running engine can cause the EEC IV feedback controls to keep that air injection pumping into the exhaust way more than it should be. As you've improved your fuel control, your PCM is picking up on it and diverting more air to atmosphere than exhaust. Hence it's quieter.

The juice may have helped in your improvements, but again, only within the fuel control arena, and definitely NOT in any physical cat therapy.

Within that fuel control arena, additives can and often are beneficial. Not as much anymore with the increasingly more precise fuel metering technology and gasoline detergent formulas, but they still help more than hurt. On older rigs that are more susceptible to injector slop--like the mechanical Bosch systems of German yore, and even our Ford EEC IV EFI systems--can benefit tremendously from liquid voodoo. I have poured a bottle into a half-tank on an old Benz or Beemer running too rich to pass emissions, take it for a rip up the mountain and back (about 25 miles of hard serpentine driving) and return with compliant emissions levels and a noticeably smoother running engine. Wow!

But of all the products I've tested (and I've run a lot of before/after a tankful fuel control analysis in my time), I'm sorry to say very little changes have been achieved with consumer blends. When there were improvements, it has always been with OBD I systems, never anything modern. And the only two that registered any improvements on the older systems are the two you have already chosen. So chances are they've had a good effect for you.

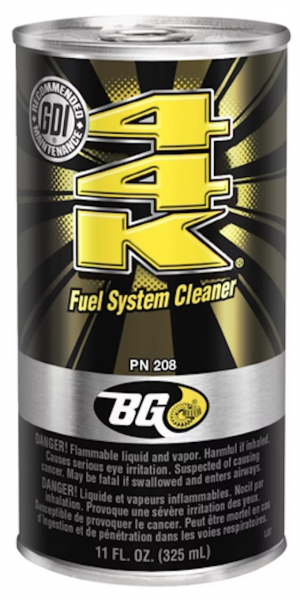

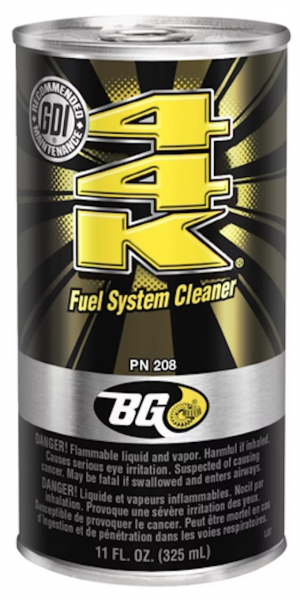

The absolute very best additive I've used is a brand long available only to commercial shops, and that's BG brand 44K blend, part no 208.

It's been on the consumer market now for some years, but no guarantees it's the same formula, especially if the pn is not 208, and definitely not the product in the plastic Techron style bottles.

If you find it, and it's the steel pop-top can with PN 208, buy it. Expect to pay $30.00 a can, but worth it.

Get the funnel kit too. Thjis stuff etches flesh, and not easy to accurately pour out of that can. The BG funnel is sized to the can and snaps on tightly.