lucky7_1080

New member

Not to sound like "that guy", but what you are saying here doesn't quite jive. How are you turning the crankshaft ?

W/ a 15/16" socket and extension directly on the crankshaft, tranny in neutral.

What is your reference point?

TDC (0deg.) is marked well on my balancer, so it's been easy to see when I'm all lined up.

If its really that inconsistent, then you might have an extremely loose timing chain that's jumping on the gears. I don't believe that is the fact here based on the fact that it runs at all.

To add a bit more clarity on the "running". To get it to fire at all I have to keep the starter engaged while its firing and bury the pedal as I let off the key. This wasn't really clear from my videos. I don't believe all cylinders are firing (also not clear from the video).

You mentioned earlier that fuel is coming from the venturis at WOT (I assume while cranking) If that is a fact, then your float level is way too high as no fuel should be seen there until high rpm.

Float is set parallel to the top of the bowl, down 1.3cm (a bit lower than the OEM float by a mm). I pulled the cover back off and bowl is half full. I don't believe that the carb is the issue.

Id go back to the float level until that is proven correct.

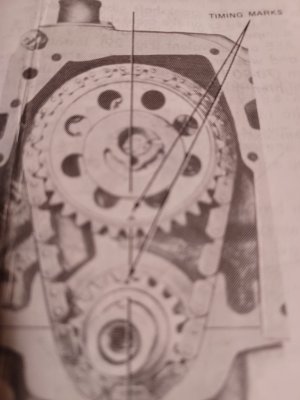

You can check the timing chain wear by lining up the 0 deg mark on the crankshaft damper with the pointer, (The rotor should point at 1 or 6 depending on which rotation you are on. (It takes 2 crank rotations to compete the 4 stroke cycle)0.

Next move the crank back and forth with a ratchet and 15\16' socket on a 6" extension. Note how far you have to rotate the crank each way before the rotor starts to move.

This is called timing chain deflection and shouldn't be more than 8 to 12 deg. (its marked on the damper there, so easy to read. Plus if your back and forth measurement is consistent, the chain and dist drive gears are not jumping.

Chain deflection is 20 degrees plus. The play is inconsistent depending on where I am with the full crank rotatation.

All that being said, I'd still stay on that float level until you are positive it is correct. It makes the most sense based on the information we have.

It can look suspicious though as you've been through the carb and the symptom appears to be the same. I believe your initial failure was a bad float or needle and seat and , if the float is set too high, the problem is the same.

Hope that helps.

Good luck

Cheers

I haven't pulled the distributor yet and am EXTREMELY nervous to do so for fear of the oil pump shaft dropping into the pan. After more discussion with local mechanics and on the forums, do you all believe that there is the possibility of the pump gears seizing? I've been researching all the reasons why the distro rotor wouldn't spin 180. When I think back to the initial event I consider what would have changed when it fired normally on the flat, and why I couldn't get it to fire on the slope.

I've ordered the parts necessary to replace the gears, chain, water pump, etc. as I've performed this service in the past. It's unclear whether gears and chain have ever been done, but water pump is at least 20 years old, as I've already had to swap at least one press-in fitting as it rusted in half.

Thanks all.

Last edited: