lynchsg

Member

If you live in a state that requires emissions testing or you just want to keep originality then every thing will have to be OEM specific.

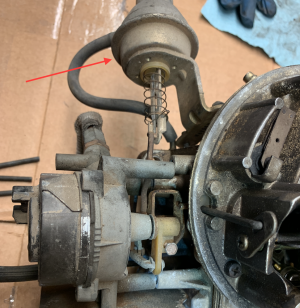

Unfortunately the EGR tube plate needs to be removed to drill out the broken tube if you can't get a hose on the broken tube end (you may have to make a new gasket...exacto blade, scissors and bulk gasket material).

The carb can be cleaned (if as mentioned the float is brass) and put back together with a rebuild kit. Old carbs tend to have warped surfaces that create vacuum leaks. So do purchased rebuilt carbs. Wether you try rebuilding your old carb or purchase a rebuilt carb, check flat surfaces with a straight edge (something you know is truly flat, within .002") and a feeler gage (.002-.003") front to back, side to side and diagonally in several places. If the .003" feeler gage passes under the straight edge you might get away with filing the flat carb surface. Usually around the bolting areas are where surfaces warp.

You can try cleaning out the EGR valve, but the internal diaphragm usually go bad with time. Replacing the EGR valve is best. They are costly. You can try cutting the EGR base gasket to match your old gasket...

I removed everything, replaced the intake and carb (with a manual choke) from Edelbrock. Also put a 14×4" K&N air filter and housing on top of the carb. But I live where there are no emissions testing.

Anyway you go, bare minimum is a lot of cleaning and checking of old parts. New EGR and rebuilt carb will cost you as will aftermarket parts.

Hope this helps some.

Unfortunately the EGR tube plate needs to be removed to drill out the broken tube if you can't get a hose on the broken tube end (you may have to make a new gasket...exacto blade, scissors and bulk gasket material).

The carb can be cleaned (if as mentioned the float is brass) and put back together with a rebuild kit. Old carbs tend to have warped surfaces that create vacuum leaks. So do purchased rebuilt carbs. Wether you try rebuilding your old carb or purchase a rebuilt carb, check flat surfaces with a straight edge (something you know is truly flat, within .002") and a feeler gage (.002-.003") front to back, side to side and diagonally in several places. If the .003" feeler gage passes under the straight edge you might get away with filing the flat carb surface. Usually around the bolting areas are where surfaces warp.

You can try cleaning out the EGR valve, but the internal diaphragm usually go bad with time. Replacing the EGR valve is best. They are costly. You can try cutting the EGR base gasket to match your old gasket...

I removed everything, replaced the intake and carb (with a manual choke) from Edelbrock. Also put a 14×4" K&N air filter and housing on top of the carb. But I live where there are no emissions testing.

Anyway you go, bare minimum is a lot of cleaning and checking of old parts. New EGR and rebuilt carb will cost you as will aftermarket parts.

Hope this helps some.