Yo tjg8675,

As Tiha advised;

"Removal

- Pull the wiring harness connector from the vehicle speed sensor (VSS) (9E731).

Vss Location:

VSS is atop 8.8 Rear Differential

- Remove the vehicle speed sensor hold-down bolt and remove the vehicle speed sensor from the axle housing.

Installation

- Clean the axle mounting surface. Use care to prevent dirt from entering the axle housing.

- Inspect and clean the magnetized vehicle speed sensor pole piece to make sure it is free from loose metal particles which could cause erratic system operation. Replace the vehicle speed sensor O-ring.

- Lightly lubricate the vehicle speed sensor O-ring with motor oil, align the vehicle speed sensor bolt hole and install. Do not apply force to the plastic vehicle speed sensor connector. The vehicle speed sensor ****** should slide to the mounting surface. This will make sure the air gap setting is between 0.127-1.14mm (0.005-0.045 inches).

- Install the vehicle speed sensor hold-down bolt and tighten to 34-40 Nm (25-30 lb-ft).

- Push the connector on the vehicle speed sensor.

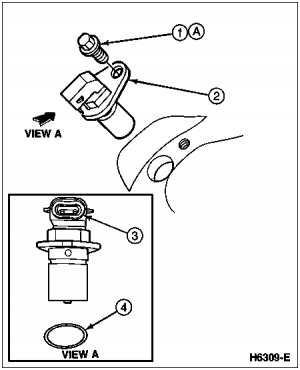

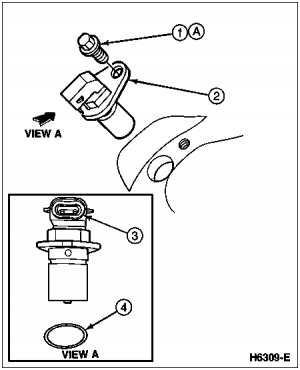

| Item | Part Number | Description |

|---|

| 1 | 390356 | Vehicle Speed Sensor Hold-Down Bolt |

| 2 | 9E731 | Vehicle Speed Sensor |

| 3 | — | Connector Seal

(Part of 2L373) |

| 4 | NBR017 | O-Ring |

| A | — | Tighten to 34-40 Nm

(25-30 Lb-Ft) |

●

ALSO:

TSB 96-21-11 Programmable Speedometer/Odometer Module Pointer Waver

Publication Date: OCTOBER 7, 1996

LIGHT TRUCK: 1992-1996 AEROSTAR, BRONCO, ECONOLINE, F-150-350 SERIES

ISSUE: The speedometer needle may waver and/or a light surge may occur on some vehicles when speed control is used at highway speeds between 80-113 km/h (50-70 mph). This may be due to slight dents/chips in either the exciter ring or the Vehicle Speed Sensor (VSS) and air gaps between the VSS and the exciter ring.

ACTION: Replace the Programmable Speedometer/Odometer Module (PSOM) if required. New PSOM's come with increased immunity to system variability. Refer to the following Diagnostic Procedure for details.

DIAGNOSTIC PROCEDURE

BRONCO/F-SERIES - Perform normal PSOM diagnostics per Pinpoint Tests "H" and "J" of the 1996 F-Series/Bronco Body/Chassis Service Manual, Pages 13-01-30 through 13-01-32 and Pinpoint "B" of the 1996 Powertrain/Drivetrain Service Manual, Page 10-03-11.

ECONOLINE - Perform normal PSOM diagnostics per Pinpoint Tests "H" and "J" of the 1996 Econoline Body/Chassis Service Manual, Pages 13-01-29 through 13-01-31 and Pinpoint "B" of the 1996 Powertrain/Drivetrain Service Manual, Page 10-03-9.

AEROSTAR - Perform normal PSOM diagnostics per Pinpoint Test "K" of the 1994 Aerostar Body/Chassis Service Manual, Page 13-01B-31.

* Any slight dents, chips, etc., in either the exciter ring or VSS will create needle waver. Measure air gap between the VSS and exciter ring. It should be 0.38-0.51mm (0.015-0.020").

* Check exciter ring runout per the same ring gear backface runout procedure of the appropriate model 1996 Powertrain/Drivetrain Service Manual, Section 05-00.

* Make sure the exciter ring is mounted correctly to the ring gear. If runout is more than 0.1mm (0.004"), perform the differential runout check per the procedure in the appropriate model 1996 Powertrain/Drivetrain Service Manual, Section 05-02A or 05-02D, to find cause and repair as needed.

* If all items listed above check good, replace the Instrument Cluster Assembly. Obtain the correct service part number from the Parts Catalogue and then contact the Electronic Odometer Exchange Center at (800) 259-9700 for U.S. Dealers and (800) 663-9974 for Canadian Dealers.

NOTE: DEALERSHIP MUST TELL THE ODOMETER EXCHANGE CENTER THAT YOU NEED A PSOM3 LEVEL CLUSTER FOR A SPEEDOMETER NEEDLE WAVER CONCERN .

OTHER APPLICABLE ARTICLES: NONE

WARRANTY STATUS: Eligible Under The Provisions Of Bumper To Bumper Warranty Coverage

OPERATION DESCRIPTION TIME

962111A Replace Programmable Speedometer/Odometer Module (PSOM) - F-Series, Bronco 0.6 Hr.

962111B Replace Programmable Speedometer/Odometer Module (PSOM) - Econoline 0.7 Hr.

962111C Replace Programmable Speedometer/Odometer Module (PSOM) - Aerostar 0.8 Hr.

*******************************