Bass2Mouth

New member

Greetings from Central Texas! I've been lurking here for a while and decided I might as well hop on.

About 6 months ago I picked up a 1991 Bronco XL from my father-in-law that used to be a New Mexico Forest Service rig. He bought it back in the early 2000s, and used it on the deer lease and as an extra vehicle for some time.

It got passed around to different people a couple times, until late 2012 when the E4OD finally started having severe tantrums. It got parked at the family feed store at that time, and has sat as a parking lot paper weight until I convinced my father-in-law it was time to get it running again.

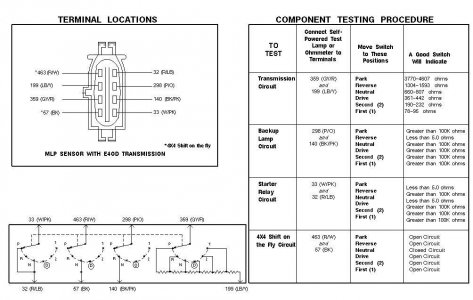

It still has a massive problem with the E4OD, it runs excellent in manual 1st gear and Reverse, however there is ZERO manual 2nd gear, and in Drive it slips pretty bad at start off and then just never really performs right, still never getting into or out of 2nd gear it feels like. I'm just running it around the pasture to the shop back and forth for now, so only having 1st gear isnt really an issue for now. I have replaced the MLPS but that didnt change any behavior.

It has a 5.0 with E4OD trans, 4.11 gears and LSD rear end. Hoping to use for a mild trail rig around the various parks here in TX, and a occasional grocery getter/sunday driver.

Pulled codes about a month ago when I finally got the 5.0 stable, spit out the following

126

172

211

543

556

I need to rerun the diagnostics as I have addressed some of those items, I need to clear the current codes first.

Things replaced since I got it:

New battery

New battery cables all around (2ga for battery, 4ga for solenoid out)

New fuel tank

New fuel pump

Repaired fuel sending unit

Replaced rear diff fluid and friction modifier

New tailgate window regulator

New Radio

New speakers

New Ignition Coil

New MAP Sensor

New Water pump

New Fan Clutch

New thermostat

New ECT sensor (to gauge)

New 2 core radiator

New plugs and plug wires

Replaced all plastic vacuum lines with new rubber vacuum lines

Patched all visible wiring that was frayed

6 inch SuperLift with extended radius arms

New drop pitman arm

New MLPS and plug

MileStar Patagonia 33s on original 15X8s

Things to address:

E4OD issues (Planning to buy a built E4OD from Monster Transmission, ~$2500 with 3 year warranty and a shop about 45 minutes away in case it ever detonates)

Service the t-case

3G alternator upgrade

Floor rust, the floor pans and cab corners in the front are gone, not sure how I'm going to handle this yet. May soundproof and rhinoline interior.

Timing adjustment to get a little more power (May need to get new distributor due to PIP sensor code being thrown)

Body panel fun stuff, possibly paint. (I think I may be able to pressure wash some of the old spray paint off, it flakes with a fingernail in a lot of areas)

ALIGNMENT (After the lift its quite visible that my camber is waaay positive)

Brake lines, (have extended stainless lines, just need to install)

Front hubs and rotors

Rear hubs and drums

Entire exhaust system (While running some seafoam the exhaust manifolds started smoking really bad, guess they got cracked from the heat, most likely will run shorty headers to a highflow cat and muffler)

Rock sliders/step rail

Front and rear bumper replacement

Would love any kind of feedback or suggestions, trying to focus on the alignment and transmission right now so I cant get this thing back on the streets and out from the pasture.

Thanks!

About 6 months ago I picked up a 1991 Bronco XL from my father-in-law that used to be a New Mexico Forest Service rig. He bought it back in the early 2000s, and used it on the deer lease and as an extra vehicle for some time.

It got passed around to different people a couple times, until late 2012 when the E4OD finally started having severe tantrums. It got parked at the family feed store at that time, and has sat as a parking lot paper weight until I convinced my father-in-law it was time to get it running again.

It still has a massive problem with the E4OD, it runs excellent in manual 1st gear and Reverse, however there is ZERO manual 2nd gear, and in Drive it slips pretty bad at start off and then just never really performs right, still never getting into or out of 2nd gear it feels like. I'm just running it around the pasture to the shop back and forth for now, so only having 1st gear isnt really an issue for now. I have replaced the MLPS but that didnt change any behavior.

It has a 5.0 with E4OD trans, 4.11 gears and LSD rear end. Hoping to use for a mild trail rig around the various parks here in TX, and a occasional grocery getter/sunday driver.

Pulled codes about a month ago when I finally got the 5.0 stable, spit out the following

126

172

211

543

556

I need to rerun the diagnostics as I have addressed some of those items, I need to clear the current codes first.

Things replaced since I got it:

New battery

New battery cables all around (2ga for battery, 4ga for solenoid out)

New fuel tank

New fuel pump

Repaired fuel sending unit

Replaced rear diff fluid and friction modifier

New tailgate window regulator

New Radio

New speakers

New Ignition Coil

New MAP Sensor

New Water pump

New Fan Clutch

New thermostat

New ECT sensor (to gauge)

New 2 core radiator

New plugs and plug wires

Replaced all plastic vacuum lines with new rubber vacuum lines

Patched all visible wiring that was frayed

6 inch SuperLift with extended radius arms

New drop pitman arm

New MLPS and plug

MileStar Patagonia 33s on original 15X8s

Things to address:

E4OD issues (Planning to buy a built E4OD from Monster Transmission, ~$2500 with 3 year warranty and a shop about 45 minutes away in case it ever detonates)

Service the t-case

3G alternator upgrade

Floor rust, the floor pans and cab corners in the front are gone, not sure how I'm going to handle this yet. May soundproof and rhinoline interior.

Timing adjustment to get a little more power (May need to get new distributor due to PIP sensor code being thrown)

Body panel fun stuff, possibly paint. (I think I may be able to pressure wash some of the old spray paint off, it flakes with a fingernail in a lot of areas)

ALIGNMENT (After the lift its quite visible that my camber is waaay positive)

Brake lines, (have extended stainless lines, just need to install)

Front hubs and rotors

Rear hubs and drums

Entire exhaust system (While running some seafoam the exhaust manifolds started smoking really bad, guess they got cracked from the heat, most likely will run shorty headers to a highflow cat and muffler)

Rock sliders/step rail

Front and rear bumper replacement

Would love any kind of feedback or suggestions, trying to focus on the alignment and transmission right now so I cant get this thing back on the streets and out from the pasture.

Thanks!