Rumbler tag

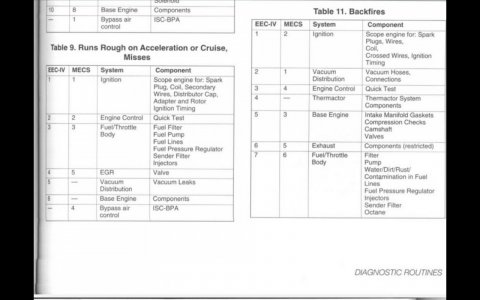

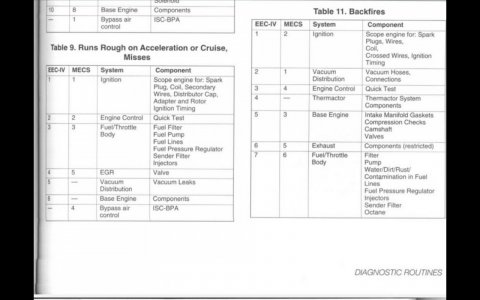

New member

This all started this summer on the way back home I was going to pass someone and when I stepped on the throttle it would **** back in forth for a bit then all of a sudden shoot up in rpm like it should backfire jump around a little and then go back down in rpm, I continued to try and make it home like that the problem became worse until finally I made it about a mile from my house and it died while I was trying to crawl it home at that point it was barely running. I let it sit for 30 minutes came back started right up then I thought I had the problem the TFI module, so I ordered a new one and replaced it(the original one was still in it after all those years) but after replacing it I found out that the new TFI didn’t change anything. I tried to drive around a bit for a couple days to maybe get an idea of what’s going on same thing I would start it up just fine and let it warm up and if I tried giving it a lot of throttle it would backfire and **** around, at that point I had given up for a bit and now I pulled codes on the thing and only got EGR codes and O2 codes, so I said hey why not replace all the sensors in the vehicle as they are all original I replaced MAP, EGR, EGR valve on the left passenger side fender, EGR pressure feedback sensor, O2 sensor, Intake charge temp sensor, coolant temp sensor, idle air control sensor, throttle position sensor. Before replacing all the sensors I decided to try and take it out to fill it up with some gas on. This is the first time I’ve fired it up in winter the thing started like normal but when I went to town it ran like a lot better in the cold it could just be a fluke. After replacing all the sensors I still have the dreaded O2 lean code and EGR stuck open or closed, I took the fusible link out of the O2 sensor wire and it got rid of the O2 code for a little bit I took it for a spin with all new sensors and the O2 sensor hot wired and it still does the same thing I’m at a loss right now hopefully someone can help, I’ve also checked all vacuum lines