Yo BlackBetty95,

WELCOME!

Here are the Ford tests for the two issues. If you need assistance just ask or at least you will know what a mechanic should do.

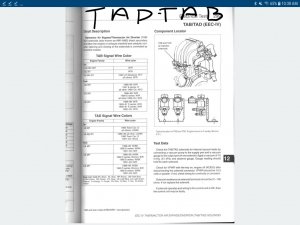

DTCs 553 indicates that voltage output for Secondary Air Injection solenoid(s) did not change when activated.

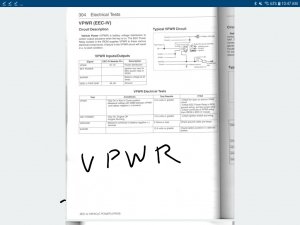

miesk5 Note; this set of tests includes use of Ford's old Break-Out Box; so, as I mentioned in another thread here in place of the break-out box, go to the EEC connector pin instead; substitute EEC connector pin Number for breakout box number, using;

EEC IV Connector Pin Diagram

Source: by Ryan M at

EEC IV Connector Pin LEGEND Bronco & Ford Truck & Van: 4.9, 460, 5.0, 5.8;

Source: by Ryan M at

Ford Fuel Injection

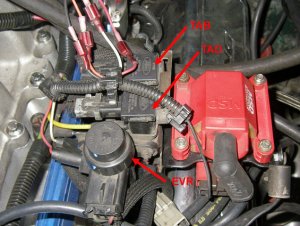

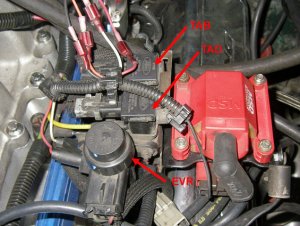

Disconnect AIRB/AIRD (TAB/TAD solenoid connector.

Key on, engine off.

Measure voltage between VPWR circuit and battery ground of one solenoid, then repeat for the other solenoid.

Is each voltage greater than 10.5 volts?

Yes GO to KC10 .

No SERVICE open harness circuit. RECONNECT both solenoids. RERUN Quick Test.

KC10 MEASURE AIRB/AIRD SOLENOID RESISTANCE

Key off.

Disconnect both AIRB/AIRD solenoid connectors and measure both solenoid resistances.

Is each resistance between 50 and 100 ohms?

Yes go to KC11 .

No REPLACE AIRB/AIRD solenoid assembly. RECONNECT both solenoids. RERUN Quick Test.

KC11 CHECK CIRCUIT CONTINUITY

Key off.

Disconnect Powertrain Control Module (PCM). Inspect for damaged or pushed out pins, corrosion, loose wires, etc. Service as necessary.

Install breakout box, leave PCM disconnected.

Measure resistance between AIRB circuit at breakout box and AIRB circuit at vehicle harness connector.

Measure resistance between AIRD circuit at the breakout box and AIRD circuit at vehicle harness connector.

Is each resistance less than 5.0 ohms?

Yes Go to KC12 .

No SERVICE open harness circuit. REMOVE breakout box. RECONNECT PCM and both solenoids. RERUN Quick Test.

KC12 CHECK FOR SHORT TO GROUND

Key off.

Breakout box installed, PCM disconnected.

Disconnect both AIRB/AIRD solenoids.

Measure resistance between AIRB circuit at the breakout box and Test Pins 40, 46 and 60. Measure resistance between AIRD circuit at the breakout box and Test Pins 40, 46 and 60 at the breakout box.

Is each resistance greater than 10,000 ohms?

Yes GO to KC13 .

No SERVICE short to ground. REMOVE breakout box. RECONNECT PCM and AIRB/AIRD solenoids. RERUN Quick Test.

KC13 CHECK FOR SHORT TO POWER

Key off.

Breakout box installed, PCM disconnected.

Both AIRB/AIRD solenoids disconnected.

Measure resistance between AIRB circuit at the breakout box and Test Pins 37 and 57. Measure resistance between AIRD circuit at the breakout box and Test Pins 37 and 57 at the breakout box.

Is each resistance greater than 10,000 ohms?

Yes REPLACE PCM. REMOVE breakout box. RECONNECT both solenoids. RERUN Quick Test.

No SERVICE short to power. REMOVE breakout box. RECONNECT PCM and AIRB/AIRD solenoids. RERUN Quick Test. If DTC is present, REPLACE PCM.

■

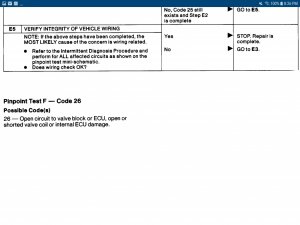

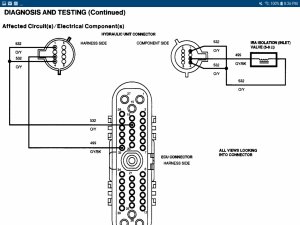

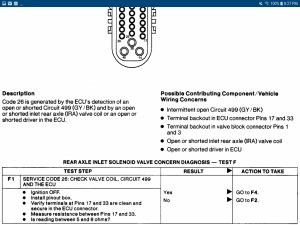

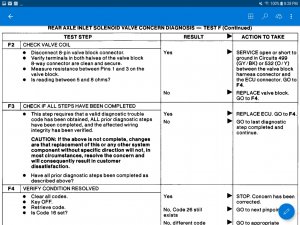

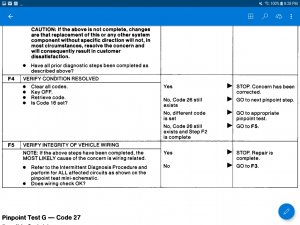

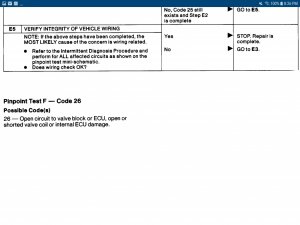

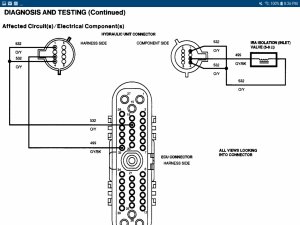

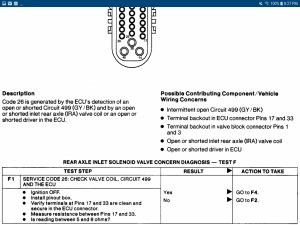

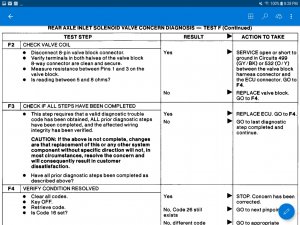

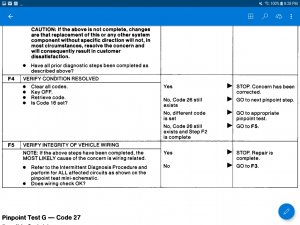

For 4WABS CODE 26, SEE ATTACHED;

⊙●⊙

Was speed control, if equipped recall work completed by dealership? Call local dealer or register and view status @

https://owner.ford.com; or @

https://vinrcl.safercar.gov/vin/ ... have VIN ready.

"Summary: ON CERTAIN PICKUP TRUCKS, PASSENGER VEHICLES, SPORT UTILITY VEHICLES, AND MOTOR HOMES CHASSIS, THE SPEED CONTROL DEACTIVATION SWITCH MAY, UNDER CERTAIN CONDITIONS, LEAK INTERNALLY AND THEN

OVERHEAT, SMOKE, OR BURN. THIS COULD RESULT IN AN UNDERHOOD FIRE."

See this guide by jowens1126 to confirm recall status @

https://www.fullsizebronco.com/foru...ruise-control-recalls-repair.html#post6530073

Note that the 93 recall is different than 94-96.

Here is the

1995 Bronco Dealer Brochure

1995 Drivetrain, Powertrain Service Manual

https://drive.google.com/open?id=1M0M9m9vtiOxwy5wkJ203tlSTjwuWzcew

1995 Body, Chassis Service Manual

https://drive.google.com/open?id=1MJ0Li_e-Esufa-pnSR-edaQ9VD15SiMS

To switch between folder list & grid views, click the button to the right of the "DOWNLOAD ALL" button in the upper right corner of the window)by HawkDriver

Free registration for some wiring diagrams (86 through 96) and Technical Service Bulletins, (80 through 96) with Recalls, same as by Ford @

BBB Industries- Premium Alternators, Starters, Power Steering Products | TSB's & Wiring Diagrams

Al