Yo AJ,

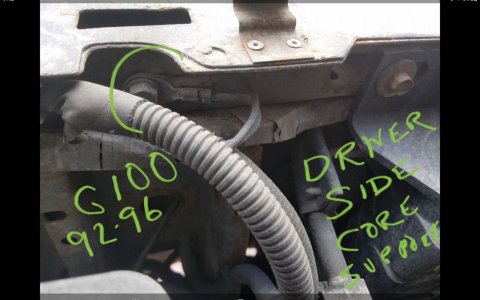

GROUND G201 IS IN DRIVER KICK PANEL

Start with

HEADLIGHT Switch Fires, Part Number SW-2103: "...Over the past two years, this office has experienced fires caused by another potential problem in Ford vehicles. The problem exists within the dimmer portion of the headlight switch in Ford vehicles. The light switch involved is a Model SW-2103. These are the pull out type headlight switches usually located in the lower left corner of the front dash of Ford vehicles. The headlight portion of the switch has two pullout positions, the first for parking lights only, and fully out for headlights and parking lights. The shaft of this pull-out light switch can be turned clockwise and counterclockwise which activates a dimmer switch, lowering and raising the intensity of the lighting in the instrument panels respectively. Fully rotating the shaft counterclockwise past a notch activates the interior lights within the vehicles. The potential problem exists within the dimmer portion of this switch. The dimmer mechanism consists of a metallic resistive coil set inside a ceramic disc positioned over the shaft of the switch. The coil is exposed on its front side away from the passenger compartment. The front side of the coil passes across a contact permitting a current to flow through a certain portion of the coil when the switch is pulled our in its first or second positions. The greater amount of coil through which the current is permitted to pass (clockwise most position) creates the greatest resistance and therefore dims the dash lighting to its lowest intensity. The opposite position provides greatest intensity. Through our investigations, we have found that the coil can fail owing to wear and/or possible material defects or damage. A fractured coil can maneuver itself free of the ceramic disc permitting it to come in contact with the metal bracket which mounts and grounds the switch to the vehicle. When this occurs, a current can flow through a portion of the coil creating high temperatures melting the metal material of the coil and possibly igniting surrounding combustibles. This mechanism has been observed in three separate incidents by this office. Two of these resulted in a fire. The mechanism is precipitated by wear and/or defect in the coil mechanism. If the former is true, we expect there will be an increase in fires caused through this mechanism given an increase in service time. To this date the problem appears to be somewhat limited. However, this particular light switch has been utilized in numerous Ford vehicles. Therefore, a small increase in failure rate owing to age and wear could result in a significant increase in fire losses. The SW-2103 Light Switch Assembly discussed above is reportedly installed in the following Ford vehicles: 1986 -1997 F100, F150, F300; 1990-1994 Explorer; 1987-1994 Ranger; 1987-1990 Bronco II; 1992-1997 Aerostar..."

miesk5 NOTE: No Bronco Listed, but this may be the result of typos or incomplete research by the company.

And some Full-Size Bronco owners have had these fires.

●

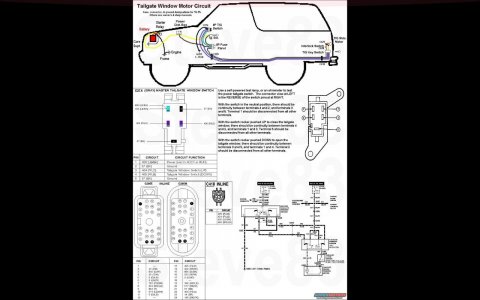

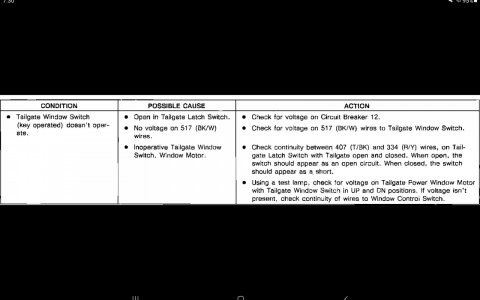

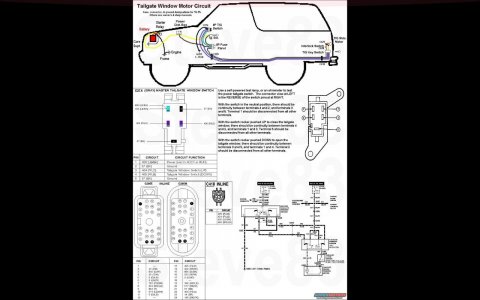

Tailgate:

All '80-96 t/g wiring runs from the dash switch (F2TZ-14529-A

Motorcraft SW7071 ~$25~65) out the firewall along the frame to the rear bumper up to the L taillight and into the t/g. '80-86 have a large round 3-wire connector in the LHR taillight well; those with rear defrost also have a 1-wire connector. All years with rear defrost have a ground ring ******* to the body in the taillight well. I think '87-91 have the large round connector in front of the taillight AND a smaller round 4-wire connector inside the frame at the LHR body mount. '92-96 only have the frame connector.

Normal operation is as follows:

RAISE from the dash switch:

Power flows thru fuse 14 thru the LB/BK wire thru the IP switch UP contacts thru the P/LG wire thru the key switch UP contacts thru the Y/R wire to the motor brushes, commutator, & windings; then it grounds thru the motor's internal CB, out thru the R/Y wire thru the latch switch thru the T/Bk wire thru the key switch DOWN contacts thru the Pk/LB wire thru the IP switch DOWN contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos).

LOWER from the dash switch:

Power flows thru fuse 14 thru the LB/BK wire thru the IP switch DOWN contacts thru the Pk/LB wire thru the key switch DOWN contacts thru the T/Bk wire thru the latch switch thru the R/Y wire thru the motor's internal CB to the motor brushes, commutator, & windings; then it grounds out thru the Y/R wire thru the key switch UP contacts thru the P/LG wire thru the IP switch UP contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos).

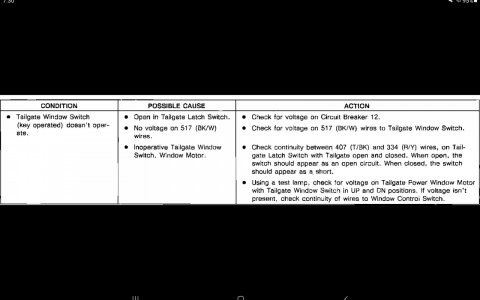

RAISE from the key switch:

Power flows thru fuse 12 thru the BK/Wh wire thru the key switch thru the UP contacts thru the Y/R wire to the motor brushes, commutator, & windings; then it grounds thru the motor's internal CB out thru the R/Y wire thru the latch switch thru the T/Bk wire thru the key switch DOWN contacts thru the Pk/LB wire thru the IP switch DOWN contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos).

LOWER from the key switch:

Power flows thru fuse 12 thru the BK/Wh wire thru the key switch DOWN contacts thru the T/Bk wire thru the latch switch thru the R/Y wire thru the motor's internal CB to the motor brushes, commutator, & windings; then it grounds out thru the Y/R wire thru the key switch UP contacts thru the P/LG wire thru the IP switch UP contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos).

Note that in ALL cases, EVERY switch is used, and the circuit ALWAYS grounds at the same point.

●

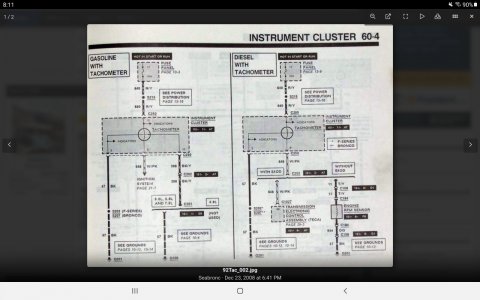

TACHOMETER: