Yo Jb,

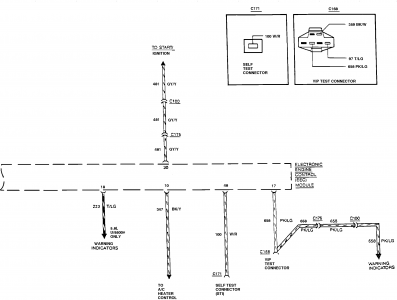

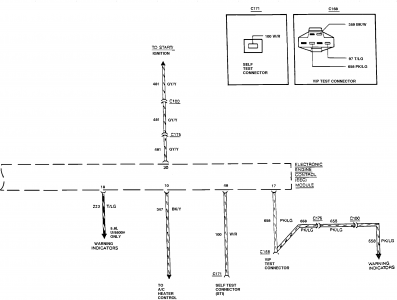

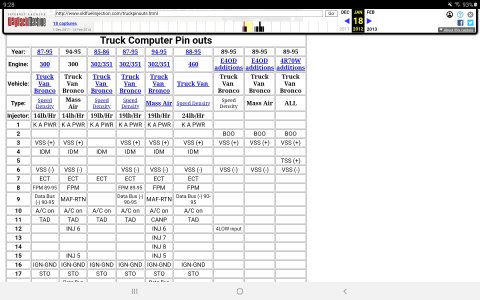

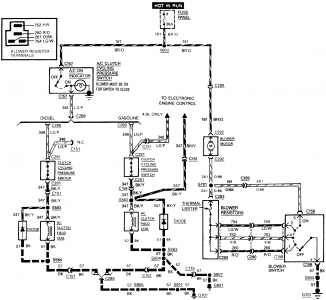

Inspect EEC IV Pins #30, #17, #48 for proper connections, bent or broken pins, corrosion, loose wires, and proper routing.

Here are some PCM KILLER perpetrators and other causes:

Smell around the PCM. If it smells like dead fish, it's bad.

Look for PCM printed circuit board burn marks around leaking capacitors, resistors.

For example, see Old leaky capacitors in swapped EEC and no more codes by jowens1126

Water damage from cowl leaks, ESPECIALLY if you you have wet carpet or mat near driver kick panel; or on PCM Connector due to a bad hood seal near cowl panel, viewable with hood up.

Corrosion or damage due to moisture is one of the main reasons for failure. Corrosion can enter through the wiring harness and moisture can enter by a failure in the seals in the PCM itself. This happens over a period of time (5 to 10 years) due to exposure to the elements.

The alternator could be generating an AC voltage spike due to bad diode(s) or supply Voltage Overloads.

I recommend bench-testing the alternator for voltage output and AC voltage ripple.

Thermal stress due to excessive heat and excessive vibration that causes sensitive parts to fail.

Bronco was jump started on reverse polarity.

Connector pin damage or corrosion,

□

Internal PCM killer perps are;

broken tracks,

cold solder joints,

short circuit,

thermal stress due to excessive heat and excessive vibration that causes sensitive parts to fail,

Overheated PC,.

Bad Intel 8061 chip or bad Intel 8361 memory chip,

Bad Internal Voltage Regulator, see Wayback Machine by Ryan M

Inspect EEC IV Pins #30, #17, #48 for proper connections, bent or broken pins, corrosion, loose wires, and proper routing.

Here are some PCM KILLER perpetrators and other causes:

Smell around the PCM. If it smells like dead fish, it's bad.

Look for PCM printed circuit board burn marks around leaking capacitors, resistors.

For example, see Old leaky capacitors in swapped EEC and no more codes by jowens1126

Water damage from cowl leaks, ESPECIALLY if you you have wet carpet or mat near driver kick panel; or on PCM Connector due to a bad hood seal near cowl panel, viewable with hood up.

Corrosion or damage due to moisture is one of the main reasons for failure. Corrosion can enter through the wiring harness and moisture can enter by a failure in the seals in the PCM itself. This happens over a period of time (5 to 10 years) due to exposure to the elements.

The alternator could be generating an AC voltage spike due to bad diode(s) or supply Voltage Overloads.

I recommend bench-testing the alternator for voltage output and AC voltage ripple.

Thermal stress due to excessive heat and excessive vibration that causes sensitive parts to fail.

Bronco was jump started on reverse polarity.

Connector pin damage or corrosion,

□

Internal PCM killer perps are;

broken tracks,

cold solder joints,

short circuit,

thermal stress due to excessive heat and excessive vibration that causes sensitive parts to fail,

Overheated PC,.

Bad Intel 8061 chip or bad Intel 8361 memory chip,

Bad Internal Voltage Regulator, see Wayback Machine by Ryan M