What is the normal state of the thermactor bypass valve on a 1989 351 windsor (no vacuum signal applied)? My valve does not hold vacuum and I would like to know if it is directing the air from the pump to the diverter or the open air when there is no vacuum applied to the diaphragm.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1989 351w thermactor bypass valve normal state

- Thread starter mikefamig

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Motech

Well-known member

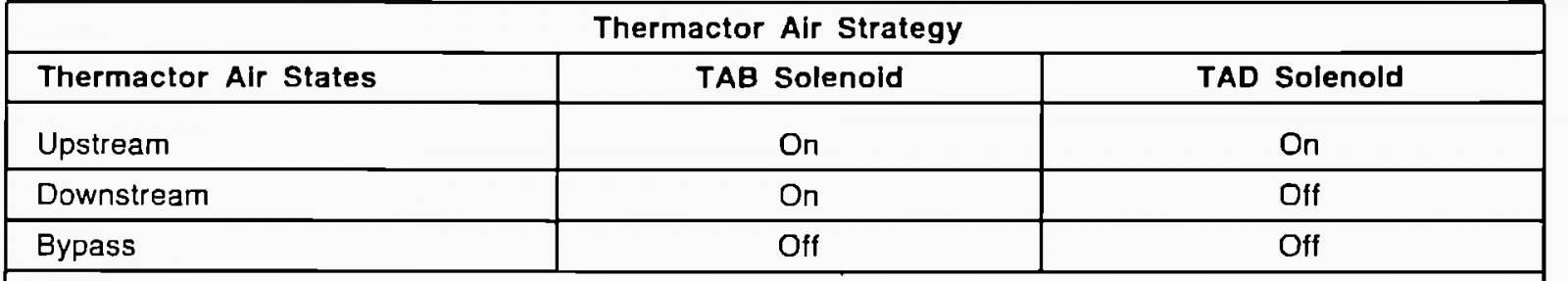

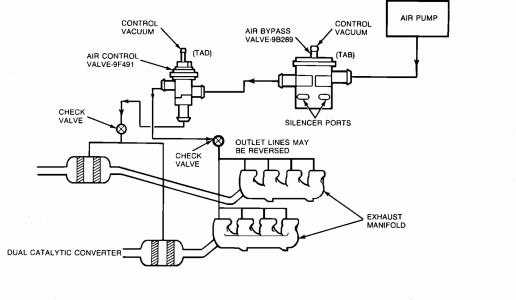

OK, here's Ford's official brevitized description, my qualifiers to follow:

Now in my diagnostic world, Normal or Normally in the description means not powered up, or at rest, or de-energized. Ford muddies the waters up there by referring to "normal" in their "energized" state.

But then they qualify that further down by saying the solenoids vent vacuum when de-energized.

That seems part of what you're asking about I think, so venting off vacuum through a metered and filtered port when not powered up is normal.

More brevitized Ford description:

When everything is in good working order, you can hear bypass occuring out that muffler in an on/off rhythm in synch with oxygen sensor feedback voltage. When O2 sensor is worn out and slow, so too is that bypass dumping rhythm.

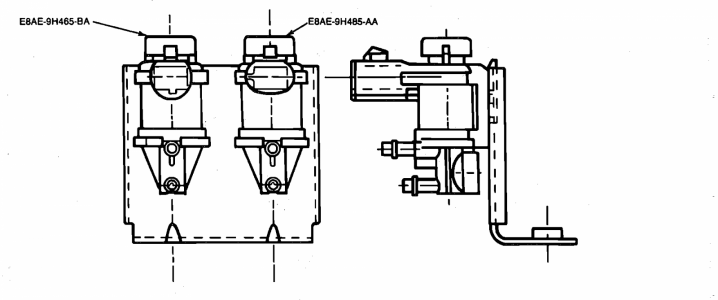

THERMACTOR AIR CONTROL SOLENOID VALVE - TAB & TAD

The Dual Thermactor Air control Solenoid Valve assembly consists of two normally closed solenoid vacuum valves, the thermactor air bypass valve and the thermactor diverter valve (TAB and TAD). When de-energized both are vented, sourced by the intake manifold vacuum reservoir...

Now in my diagnostic world, Normal or Normally in the description means not powered up, or at rest, or de-energized. Ford muddies the waters up there by referring to "normal" in their "energized" state.

But then they qualify that further down by saying the solenoids vent vacuum when de-energized.

That seems part of what you're asking about I think, so venting off vacuum through a metered and filtered port when not powered up is normal.

More brevitized Ford description:

1989 Ford Truck Bronco Full Size V8-351 5.8L

Managed Air Thermactor System

Description and Operation

Light Duty

The Thermactor (air injection) Exhaust Emission Control System reduces blah blah blah...

blah blah...

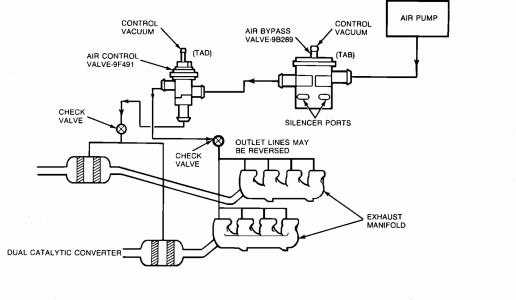

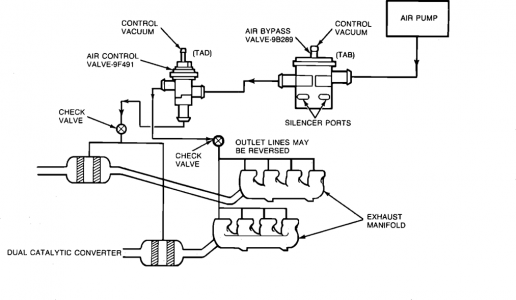

An air control valve (Thermal Air Diverter) is used to direct the air either upstream or downstream.

An air bypass valve is used to dump air to atmosphere.

blah blah-biddy...

System Description - Light Duty

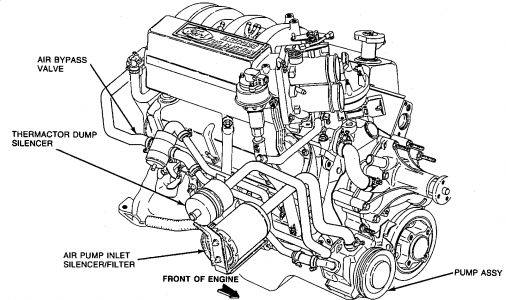

A typical air injection system may contain the following components:

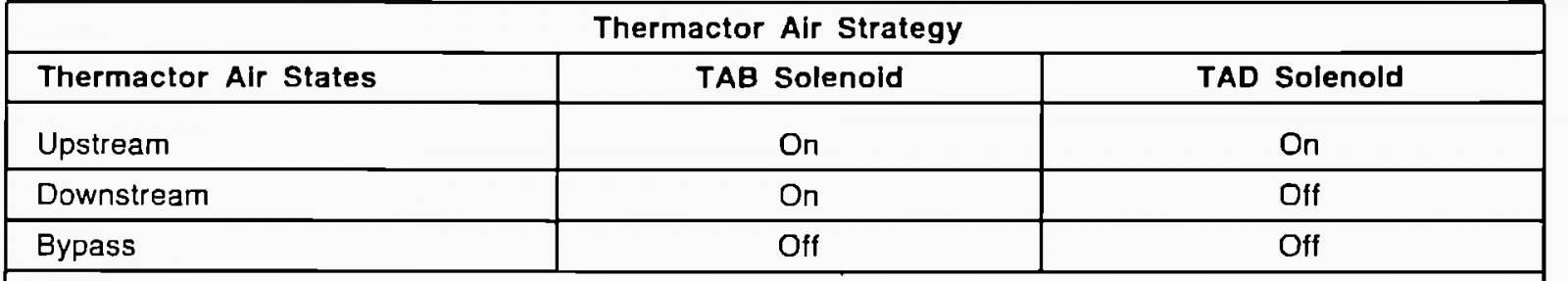

Air supply pump

Air bypass valve TAB

Check valve(s)

Air manifold

Air hoses

Air control valve (TAD)

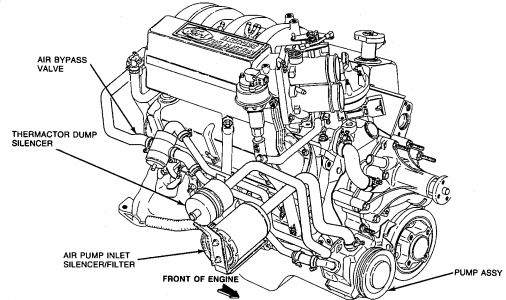

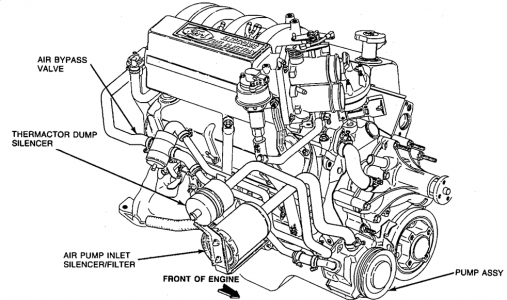

Typical Managed Air Thermactor System

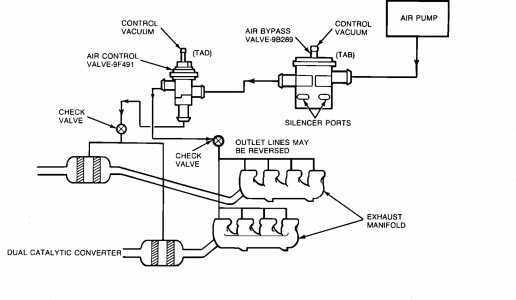

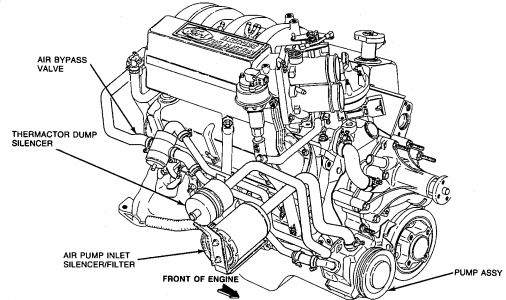

The operation of air is as follows:

1. The air is sent upstream (to exhaust manifold) when the engine is first started and the catalyst is still cold.

Here are the remaining answers:2. The air is dumped or bypassed to atmosphere when the exhaust is rich. This prevents backfire and catalyst damage along with removing the pump load from the engine.

3. The air is sent downstream (to catalyst) after the engine and catalyst are warmed up.

- Vacuum applied to TAB valve will direct pumped air into TAD valve, then to exhaust from there

- Vacuum removed from TAB valve will bypass exhaust altogether and dump flow to atmosphere through the muffler shown above

- Vacuum applied to TAB will route pumped air upstream to exhaust ports at backside of cylinder heads

- Vacuum removed from TAD will route pumped air downstream to catalytic converter

When everything is in good working order, you can hear bypass occuring out that muffler in an on/off rhythm in synch with oxygen sensor feedback voltage. When O2 sensor is worn out and slow, so too is that bypass dumping rhythm.

OK, here's Ford's official brevitized description, my qualifiers to follow:

Now in my diagnostic world, Normal or Normally in the description means not powered up, or at rest, or de-energized. Ford muddies the waters up there by referring to "normal" in their "energized" state.

But then they qualify that further down by saying the solenoids vent vacuum when de-energized.

That seems part of what you're asking about I think, so venting off vacuum through a metered and filtered port when not powered up is normal.

More brevitized Ford description:

Here are the remaining answers:

View attachment 30478

- Vacuum applied to TAB valve will direct pumped air into TAD valve, then to exhaust from there

- Vacuum removed from TAB valve will bypass exhaust altogether and dump flow to atmosphere through the muffler shown above

- Vacuum applied to TAB will route pumped air upstream to exhaust ports at backside of cylinder heads

- Vacuum removed from TAD will route pumped air downstream to catalytic converter

When everything is in good working order, you can hear bypass occuring out that muffler in an on/off rhythm in synch with oxygen sensor feedback voltage. When O2 sensor is worn out and slow, so too is that bypass dumping rhythm.

Is this information from the factory service manual?

Motech

Well-known member

Yes

Motech

Well-known member

I really edited a bunch out of there. If you'd like all the data available on that system, I'm glad to shoot you some PDF copies in a private message so it doesn't clog up your thread.

BTW, are you getting some TAB codes?

BTW, are you getting some TAB codes?

No, no codes but the bypass valve does not hold vacuum.

I think that my Father-in-law may have the factory manual, I have to search his garage for it. The Bronco is his but he is in a long term care facility after a stroke. This is why I have so many cars in my SIG file, this is his cars and mine combined.

I said that my bypass valve is not holding vacuum but I'm not absolutely sue that it is the bypass and not the diverter. It is the valve that is just to the rear of the smog pump. There is another behind the passenger side cylinder head and I'm not sure which is diverter and which is bypass.

Motech

Well-known member

Pics I posted ^up there^

Bypass valve is up front, and it has two outlets:

That system will set a running On-Demand code if there are Thermal Air Injection issues. Only in On-Demand Self Test mode though.

Most common issues are broken nylon vacuum lines and failing vacuum solenoids, which are becoming harder and harder to source though, and if I cannot resurrect them with a little violent shock therapy, I will substitute some compatible solenoids that are available.

I would not sweat it though if there is no grief involved. It almost sounds like you're diagnosing a problem you may not even have.

What's that tried-n-true redneck aphorism?

"Don't sweat the petty stuff when you could go forth and pet the sweaty stuff"

Bypass valve is up front, and it has two outlets:

- Hose connecting to Diverter Valve in the rear

- Dump hose, which routes through a muffler

That system will set a running On-Demand code if there are Thermal Air Injection issues. Only in On-Demand Self Test mode though.

Most common issues are broken nylon vacuum lines and failing vacuum solenoids, which are becoming harder and harder to source though, and if I cannot resurrect them with a little violent shock therapy, I will substitute some compatible solenoids that are available.

I would not sweat it though if there is no grief involved. It almost sounds like you're diagnosing a problem you may not even have.

What's that tried-n-true redneck aphorism?

"Don't sweat the petty stuff when you could go forth and pet the sweaty stuff"

Hey M/T- Normally open/Normally closed seems to be a relative state to some so-called engineers.

Another case of that which makes those who fix really get a hankerin to channel that 'inner Will Smith'

Another case of that which makes those who fix really get a hankerin to channel that 'inner Will Smith'

Like Earl Pitts said- Wake up, America!

Like Earl Pitts said- Wake up, America!

Is there a method to tell if the bypass valve is working?.. in another thread I have landed on code 44... my bypass gets vacuum from the TAB solenoid.. code 44 doesnt help directly identify the culprit so I would like to investigate without removing it if possibleI really edited a bunch out of there. If you'd like all the data available on that system, I'm glad to shoot you some PDF copies in a private message so it doesn't clog up your thread.

BTW, are you getting some TAB codes?

Motech

Well-known member

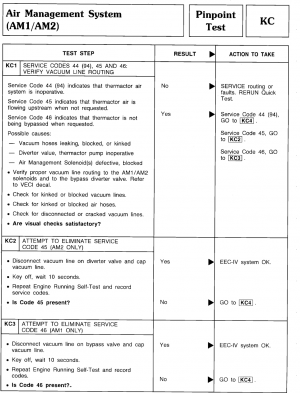

Is there a method to tell if the bypass valve is working?.. in another thread I have landed on code 44... my bypass gets vacuum from the TAB solenoid.. code 44 doesnt help directly identify the culprit so I would like to investigate without removing it if possible

- First, are you recording DTC 44 during KOER self-test?

- Secondly, if you are, should you even care?

I sure as fart hope you're referring to a 1989 Bronco 5.8

For some Toyota-type reason I can't understand, these older, 2-digit code EEC IV systems do not monitor TAB and TAD solenoid circuits for faults.If they did, they'd code during KOEO On-Demand tests, and would also set CONT codes. But they don't.

(They do for the EGR solenoid, go figure)

I guess they figured they'd lump them into a couple of running tests that cover the entire AIR system performance, and if t codes, go figure out what it is.

Hence, we get the head-scratching, all-rounder code 44: "THERMACTOR AIR SYSTEM INOPERATIVE"

Ford figures we are smart enough to cover the basic mechanical stuff, so they don't. Please do before diving into the boxes below:

- Check your pump belt tension

- Check the pulley spins the pump

- Check the pump pumps air BEFORE the valves, even if you have to remove a couple of bolts or the hose from back of the pump

- And check your vacuum ins & outs

Historically, with age comes wear. The nylon vacuum hoses are the biggest culprits, and a BIG clue to that is if you also get EGR performance codes during your KOER self-test. (Not EGR position sensor range codes; they all set those, and most all of us ignore them as long as they pass all other KOER tests)

Anyway, the name of the running code 44 game here is process of elimination, and you'll start with those biggest culprits.

So first you shore up all your vacuum hoses. You will find all red hoses trace back to one fat red source on top of the plenum, then tee off from there. Each solenoid must be getting a strong manifold vacuum signal from the red hoses, which often requires breaking them out of their plastic conduit to splice little hoses between their cracked and broken red lines. Then you do the same for all the hoses leading out of the solenoids too, repairing what you see is busted. Don't be afraid to grab them, twist and tug a little because sometimes you cannot see the breaks, and they will show up under duress.

Once that's done, run your KOER self-test again. If it's fixed, code 44 won't come back.

(Which is the genius of Ford's EEC IV: On Demand KOER Self Test is not just for reporting problems, but for fix verification. If you fixed it with a vacuum hose repair, there are no lingering questions. No KOER code anymore? It's fixed, have a nice day)

Though it often is, nowadays it's not always so simple; as these systems age further, more stuff wears out.

Next most common cause of DTC 44 is worn out solenoids. Testing is straight forward, but I'm not going to write another seven paragraphs on Break Out Box and DVOM voltage/current testing. Even though my tests are way quicker and cleaner than Ford's, they are definitely outside the box, and we need those boxes even if they do run us in circles more often than not.

And circles you will run if you skip or make errors in any of the steps they lay out.

And, AND...

They do not tell; you what you are testing, why the values matter of what reactions they will cause. They were written by engineers who assume we're all too dumb to grasp "theory", so they dumb it down by not muddying our brains with what only their superior domes can factor. Don't ask questions, just measure and move with the arrows.

But you asked for it (I think)

System Description - Light Duty

The Thermactor (air injection) Exhaust Emission Control System reduces the hydrocarbon and carbon monoxide content of the gases by continuing the combustion of unburned gases after they leave the combustion chamber by injecting fresh air into the hot exhaust stream leaving the exhaust ports. At this point, the fresh air mixes with hot exhaust gases to promote further oxidation of both the hydrocarbons and carbon monoxide, thereby reducing their concentration and converting some of them into harmless carbon dioxide and water. During different engine operations, such as cruise and WOT, the thermactor air is dumped to atmosphere to prevent overheating in the exhaust system. A typical air injection system may contain the following components:

- Air supply pump

Air Bypass Valve - TAB

Check valve

Air manifold

Air hoses

Air Control Valve - TAD

Typical Managed Air Thermactor System

The Managed Air Thermactor System is utilized in electronic control systems to divert thermactor air either upstream to the exhaust manifold check valve or downstream to the rear section check valve and dual bed catalyst.

The system will also dump thermactor air to atmosphere during some operating modes. An air control valve is used to direct the air either upstream or downstream. An air bypass valve is used to dump air to atmosphere. This system is used with a three-way catalyst and can be electronically or non-electronically controlled. The operation of air is as follows:

- The air is dumped or bypassed to atmosphere when the exhaust is rich. This prevents backfire and catalyst damage along with removing the pump load from the engine.

- The air is sent upstream (to exhaust manifold) when the engine is first started and the catalyst is still cold.

- The air is sent downstream (to catalyst) after the engine and catalyst are warmed up.

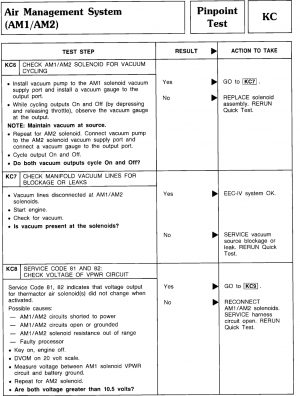

KC Test Notes

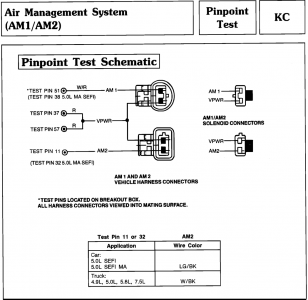

KC Pinpoint Test Schematics

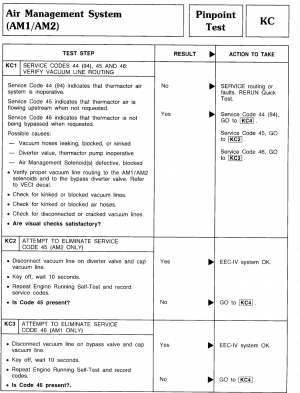

Pinpoint Tests KC1 thru KC3 - Air Management System

Pinpoint Tests KC1 thru KC3 - Air Management System

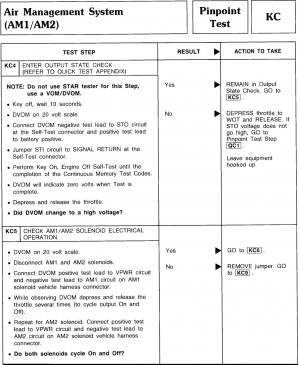

Pinpoint Tests KC4 thru KC5 - Air Management System

Pinpoint Tests KC6 thru KC8 - Air Management System

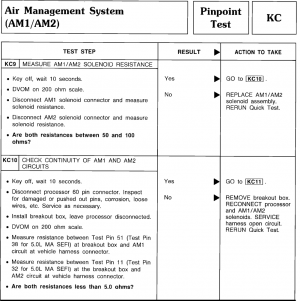

Pinpoint Tests KC9 and KC10 - Air Management System

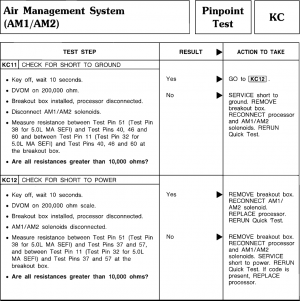

Pinpoint Tests KC11 and KC12 - Air Management System

Attachments

What is the normal state of the thermactor bypass valve on a 1989 351 windsor (no vacuum signal applied)? My valve does not hold vacuum and I would like to know if it is directing the air from the pump to the diverter or the open air when there is no vacuum applied to the diaphragm.

I have a NOS motorcraft air diverter valve... not the bypass, but in case you are checking it out too along the way, as I am checking into my bypass valve like you are ... in the non charged energized state.. like just sititng in my hand state... blowing through the larger port freely runs air down the down port. However... breathing into the smaller port (not the vacuum ******) a small amount of air does bypass the valve and can come out either the bottom port or the large port.. like 20% so its not a tiny leak or anything, seems deliberate by design.. .. if you plug both ports nothing escapes... but unplug one or the other and a little gets through the other. Actuating the vacuum action via the ****** the valve has a very soft rubbery clunkity clunk back and forth (up and down actually) feel... I can see how if you were pulling a very small amount of vacuum at idle, or had a leak... it wouldn't work.. normal vacuum especially above idle would definitely easily actuate the valve. hope that helps someone.

I stiil might care though.. if the bypass or diverter are not working or not working well and it doesnt matter except passing emmissions.... ok thats one thing... but if its causing my engine exhaust to run hot on the passenger side I care because I have burned up spark plug wires several times over the last 15 years. Ultimately I want to find a definitive guide on removing all the thermacter stuff with engine in car. I dont have emmissions to worry about.I have a 90 5.8 bronco centurion.. and get 44 on KOER... truck runs great... all the easy checks done good ... I am liking the don't care part a lot. The rest of the info fabulous too.

Motech

Well-known member

Ultimately I want to find a definitive guide on removing all the thermacter stuff with engine in car. I dont have emmissions to worry about.

I doubt you're going to find a definitive guide on how to illegally tamper with and disable your emissions control devices.

But if that's what you want to do, just remove every piece of the air injection system. Pump, components, plumbing, etc.

You'll need to find a way to block off the three inlet ports: two of them on back of the cylinder heads and one going into the catalytic converter.

You can easily pinch off the pipe going into the cat, even braze the pinched off and completely shut if you want.

On the cylinder heads, the easiest thing is to pop in a freeze plug that fits the exhaust holes, or cut off and pinch or cap the pipes.

Nothing illegal (where I live) I could drop a 347 stroker with dual exhaust.. headers.. etc if I wanted too . If I can't find parts.. like tab/tad solenoids ... not feeling too illegal about it. Like.. having a bad running thermactor system how much worse is that compared to just removing all the dysfunctional stuff? I want to fix my thermactor but I be vexxed by demons trying to do it.. doubt there is shop that can do any better... my father owns/runs an old school shop and he wouldnt even try to fix it... his mechanics just laughed at me.. cant get the parts.. I called 4 different truck salvage yards and they have zero 5.8l trucks available to even pull parts if I wanted too. People have done it... seen youtube videos .. its possible.I doubt you're going to find a definitive guide on how to illegally tamper with and disable your emissions control devices.

But if that's what you want to do, just remove every piece of the air injection system. Pump, components, plumbing, etc.

You'll need to find a way to block off the three inlet ports: two of them on back of the cylinder heads and one going into the catalytic converter.

You can easily pinch off the pipe going into the cat, even braze the pinched off and completely shut if you want.

On the cylinder heads, the easiest thing is to pop in a freeze plug that fits the exhaust holes, or cut off and pinch or cap the pipes.

Motech

Well-known member

Ahh, ok. You were responding to yourself up there.

Never mind.

Never mind.

I started this thread and spent a load of time learning about the thermactor system and how it works and I think that I understand it now. I was able to determine that my system is working well with the exception that the TAB/bypass valve diaphragm is leaking vacuum but is still functional.Nothing illegal (where I live) I could drop a 347 stroker with dual exhaust.. headers.. etc if I wanted too . If I can't find parts.. like tab/tad solenoids ... not feeling too illegal about it. Like.. having a bad running thermactor system how much worse is that compared to just removing all the dysfunctional stuff? I want to fix my thermactor but I be vexxed by demons trying to do it.. doubt there is shop that can do any better... my father owns/runs an old school shop and he wouldnt even try to fix it... his mechanics just laughed at me.. cant get the parts.. I called 4 different truck salvage yards and they have zero 5.8l trucks available to even pull parts if I wanted too. People have done it... seen youtube videos .. its possible.

I also searched for parts and I think that I have learned that there is more than one bypass valve made by ford for 351 and 302 engines that would work acceptably with the 89 351w but it would take some adapting of plumbing and what not. The valve simply opens and closes based on it's respective TAB and TAD solenoid which is controlled by the computer. I suspect that any Ford TAB valve that fits the plumbing would serve the purpose.

So after learning how the system works and learning that it is certainly possible to get acceptable parts to make the system function properly I came to the conclusion that in most cases it is not feasible to do. I would dare to say that many agree with that conclusion based on the fact that most of these thermactor systems ended up as scrap metal. Anything can be fixed but many things are not worth the time, money and effort to fix them.

The part number on the bypass valve in my Bronco is E8TE-9B289-AA and the diverter valve part number E47E-9F491-BA.

A quick test that I did convinced me that the bypass valve was functioning. I started the engine cold when it was well below the 50 degree open/close threshhold of the computer program and I could feel a strong stream of air exiting the exhaust pipe of the air pump. When the engine warmed up there was no longer air exiting the exhaust. This proves that the computer is sending a signal to the TAB solenoid based on the temp sensor in the intake manifold, the solenoid is reacting to that signal and sending engine vacuum to the bypass valve and the bypass valve is opening in response to the engine vacuum.

Last edited:

It's not a simple matter to remove the emission system because the computer unit is delivering fuel mix based on signals it receives from the system's sensors but I'm certain that it's been done countless times and you should be able to find what's necessary to make it run right on the net. It's a matter of stripping the system from the engine and then dealing with the ECU to manage the EFI.I stiil might care though.. if the bypass or diverter are not working or not working well and it doesnt matter except passing emmissions.... ok thats one thing... but if its causing my engine exhaust to run hot on the passenger side I care because I have burned up spark plug wires several times over the last 15 years. Ultimately I want to find a definitive guide on removing all the thermacter stuff with engine in car. I dont have emmissions to worry about.

I have seen videos where the air pump has been bypassed successfully, I'm just not ambitious enough to pursue all this as long as the system is still working for me.

Last edited:

Similar threads

- Replies

- 27

- Views

- 3K