So it sounds like i have to create the issue then measure voltage at both pumps? Or put 2 lites in the cab with wires connecting in front of both pumps to witness dimming as voltage drop? Or run an indepent power and ground to 1 pump at a time to see if issue still occurs? Or ______? Thanks for ideas?

As a general rule,

with any intermittent problem/condition, the best time to get the clearest idea of what

is working properly

and what is not working properly would be while that problem or abnormal condition exists. (Even if you can only determine what is still working properly it still narrows down the possibilities.)

Also, when trying to nail down an elusive problem/condition,

do not change anything about the conditions that exist during the time that the abnormal action is typically taking place

while doing the observation. Doing so only adds additional variables to the situation and multiplies the possibilities for the cause of the problem/condition.

By that I mean you should not be doing things such as adding a load to or removing a load from the circuit you are studying, and not be changing the power routing, or altering any grounds before or during the testing.

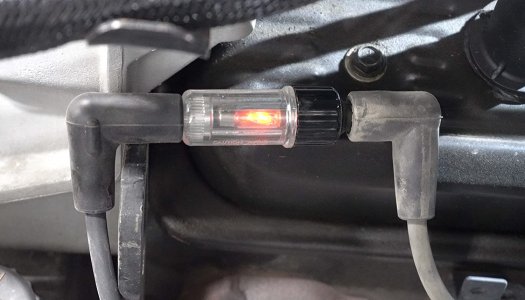

Using a self-powered meter (has a battery)

, I would check the voltage momentarily at each pump several times while they are running properly, and then recheck the voltages

the instant the problem starts.

Do not leave the meter connected in between readings.

You would do well to also check for the

amperage draw of each pump while the engine is running normally and again when it begins to stumble.

If there happens to be something wrong with the high (or low) pressure pump-for example if it were to suddenly develop more internal resistance to its pumping action after operating for a period of time that would tend to immediately increase its current requirement as it attempts to continue to operate.

As big of a pressure drop as you describe it, if it is caused by one of the pumps themselves, would almost certainly require a sizeable difference in either voltage or amperage from what they read while both are operating normally.