Seabronc

New member

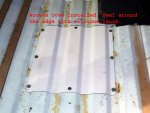

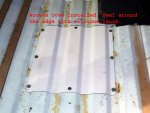

Attached are some pictures of the sender unit access panel I made for my truck. The comments in the pictures are intended to be self explanatory. I did this with the tank in place, but if you want to do it and that makes you nervous or you are not sure of your ability to control a saw, drop the tank.

1. Obtain some bed material. I got mine from the bed of a junk Bronco, F-series beds are made of the same material so you could cut a piece from there also. A drill, hole cutter (to make a hole for the next tool) and a good cordless reciprocating saw (take two batteries just in case ).

2. I located the sender in relation to the bed and body cross member. There is a cross member just in front of the sender. If you look at the bed portion of the latch that holds the rear seat down, the cross member is 12" from the rear bolt.

3. In the pictures, you will note I cut 6 holes. Originally I cut the top 4 but decided to expand the hole to include access to the vent. The holes were cut with fear and trembling since I wasn't too sure of the clearance from the bed to the tank. If you do it make sure you have control and can stop as soon as the cutter goes through. The center holes revealed the hose to the vent which was good information for the next step.

4. I used my handy dandy 18V cordless reciprocating saw held at a very shallow angle to cut between the holes. After that I filed the edges smooth.

You could also use a cutoff wheel, but I chose the saw since the wheel generates tons of sparks. The saw, on the other hand, needs to be carefully controlled and used at a shallow angle plus keeping the penetration down to about 1/2 inch.

5. The distance from top edge to bottom edge is 12" just like the top line is 12" from the seat anchor bolt. The width as you can see is the center of the rib on each side of panel center. I then fabricated my cover from the previously obtained bed material, painted, drilled holes for self tapping bolts and installed it. I used self tapping screws for the center rib attachment.

6. I then ran a light bead of silicone caulk around the edge to keep water out of my truck.

1. Obtain some bed material. I got mine from the bed of a junk Bronco, F-series beds are made of the same material so you could cut a piece from there also. A drill, hole cutter (to make a hole for the next tool) and a good cordless reciprocating saw (take two batteries just in case ).

2. I located the sender in relation to the bed and body cross member. There is a cross member just in front of the sender. If you look at the bed portion of the latch that holds the rear seat down, the cross member is 12" from the rear bolt.

3. In the pictures, you will note I cut 6 holes. Originally I cut the top 4 but decided to expand the hole to include access to the vent. The holes were cut with fear and trembling since I wasn't too sure of the clearance from the bed to the tank. If you do it make sure you have control and can stop as soon as the cutter goes through. The center holes revealed the hose to the vent which was good information for the next step.

4. I used my handy dandy 18V cordless reciprocating saw held at a very shallow angle to cut between the holes. After that I filed the edges smooth.

You could also use a cutoff wheel, but I chose the saw since the wheel generates tons of sparks. The saw, on the other hand, needs to be carefully controlled and used at a shallow angle plus keeping the penetration down to about 1/2 inch.

5. The distance from top edge to bottom edge is 12" just like the top line is 12" from the seat anchor bolt. The width as you can see is the center of the rib on each side of panel center. I then fabricated my cover from the previously obtained bed material, painted, drilled holes for self tapping bolts and installed it. I used self tapping screws for the center rib attachment.

6. I then ran a light bead of silicone caulk around the edge to keep water out of my truck.

Last edited by a moderator: