husmann

Member

My 1993 Bronco has a fuel gauge that is stuck past full.

So, for years I had a dead fuel gauge that read "Empty" all the time. Last summer I put a new fuel pump in the tank and replaced the float, that of course had a leak in it. After that, it worked like a charm, it was a true beauty, I just couldn't believe I was driving a truck that had a working fuel gauge, it was like Christmas every day! Then, I went to the self-serve car wash, pressure washed the engine bay and underbody, and then the gauge pegged past full.

When I turn the ignition on, it sweeps to empty, but when the engine is started and running, it always stays past full.

I've done some reading on the Zone and know that it is likely a dead connection or a dead sender.

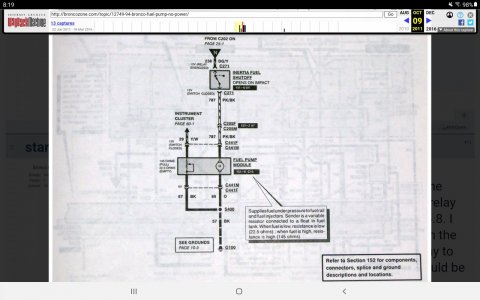

I checked the Ohms at the tank connection, and it reads 120, which is correct for the amount of fuel in the tank. So I don't think that it is the sender (I could be wrong, but I hope not, cause I've taken that tank off way too many times). It seems that the wire from the connector to the firewall is intact, but I haven't checked it thoroughly. So I decided to check the connections at the instrument cluster. I cleaned the contacts, but no luck, still pegged. I checked the Resistance at the instrument plug for the fuel gauge, but it read 77 Ohms. I will say that the yellow wire that coincides with the sender did not match up to the contact that goes to the fuel gauge on the instrument cluster contact sheet. This is something I have no explanation for.

Also, I did clean up the ground bolt and wire ends at the front left firewall, just to make sure.

Any thoughts? Should I check the resistance at the connector on the firewall? Is it possible that this could be a bad instrument cluster gauge?

Also, I'm pretty sure that there is not a fuse that goes to the sender, so I haven't checked any fuses. Am I right about that?

I am finally on schdule to get it painted on February 7, which will take my ride to the next level. I figure that a beautiful last gen Bronco should have a working fuel gauge.

Much thanks for any help.

So, for years I had a dead fuel gauge that read "Empty" all the time. Last summer I put a new fuel pump in the tank and replaced the float, that of course had a leak in it. After that, it worked like a charm, it was a true beauty, I just couldn't believe I was driving a truck that had a working fuel gauge, it was like Christmas every day! Then, I went to the self-serve car wash, pressure washed the engine bay and underbody, and then the gauge pegged past full.

When I turn the ignition on, it sweeps to empty, but when the engine is started and running, it always stays past full.

I've done some reading on the Zone and know that it is likely a dead connection or a dead sender.

I checked the Ohms at the tank connection, and it reads 120, which is correct for the amount of fuel in the tank. So I don't think that it is the sender (I could be wrong, but I hope not, cause I've taken that tank off way too many times). It seems that the wire from the connector to the firewall is intact, but I haven't checked it thoroughly. So I decided to check the connections at the instrument cluster. I cleaned the contacts, but no luck, still pegged. I checked the Resistance at the instrument plug for the fuel gauge, but it read 77 Ohms. I will say that the yellow wire that coincides with the sender did not match up to the contact that goes to the fuel gauge on the instrument cluster contact sheet. This is something I have no explanation for.

Also, I did clean up the ground bolt and wire ends at the front left firewall, just to make sure.

Any thoughts? Should I check the resistance at the connector on the firewall? Is it possible that this could be a bad instrument cluster gauge?

Also, I'm pretty sure that there is not a fuse that goes to the sender, so I haven't checked any fuses. Am I right about that?

I am finally on schdule to get it painted on February 7, which will take my ride to the next level. I figure that a beautiful last gen Bronco should have a working fuel gauge.

Much thanks for any help.