Yo Pamm,

Welcome!

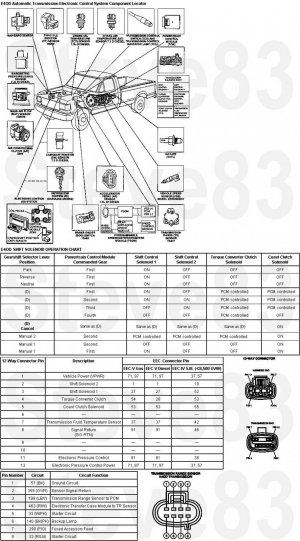

E4OD Transmission Control Indicator Light (TCIL) is the LED with an overdrive on/off switch at end of the Transmission shifter stalk; flashing OD light is an indication of a transmission related trouble code in the Powertrain Control Module (PCM).

The transmission control switch is a momentary contact switch. When the switch is pressed, a signal is sent to the powertrain control module (PCM) (12A650). The powertrain control module then energizes the transmission control indicator lamp and the coast clutch solenoid, applying the coast clutch to provide engine braking and cancels fourth gear operation; does it cause the lamp to glow?

The TCIL indicates:

overdrive cancel mode activated (lamp on), The PCM will turn on the TCIL to indicate that the overdrive cancel mode has been selected.

Or electronic pressure control circuit shorted or monitored sensor failure (lamp flashing).

sensor failure (lamp flashing).

Some non internal E4OD POSIBLE PERPETRATORS ARE:

vehicle wiring harness,

powertrain control module,

throttle position sensor,

Transmission Range (TR) sensor,

vehicle speed sensor.

shift linkage is damaged, or misadjusted

Try a Self Test for Diagnostic Trouble Codes (DTC)s by my pal, BroncoJoe19 @

Code Reader

EEC AKA PCM, computer stores the Self-Test program in permanent memory. When activated, Self-Test checks the EEC system by testing memory integrity and processing capability, and verifies that various sensors and actuators are connected and operating properly.

The EEC will tell you what it found out by testing your sensors, and also any stored information it saved from anything that went wrong during the last 40 trips.

The engine temperature must be greater than 50° F for the Key On Engine Off (KOEO) Self-Test and greater than 180° F for the Key On Engine Running (KOER) Self-Test.

Run it around to heat the engine up and shift thru all gears including Reverse. Make sure A/C is off and transmission is in Park (automatic); or in Neutral for a Manual & release clutch. Then turn off engine, all accessories/lights (close driver's door) , etc.

Do KOEO test First. Post Code(s) here according to KOEO & KOER.

A helper can assist you by counting the codes. Some use their smart phones to record them.

BEWARE OF FAN, BELTS, PULLEYS, HOT HOSES, IGNITION HIGH TENSION WIRES, AND ENGINE COMPONENTS

Or ask local mom and dad parts stores if they will test it for you.

Or purchase a coder reader such as Equus 3145 Innova OBD 1 Code Reader for Ford EEC IV Engines at Walmart & most parts stores.

●

ASAP, find out if speed control recall work, if equipped was completed. If you still have concerns about Recalls, please contact the Ford Customer Relationship Center:

US: 800-392-3673 | CA: 800-565-3673

Note: 3673 spells "FORD" on phone keys

For the hearing- or speech-impaired: Please contact the Telecommunication Relay Service by dialing 71

"Summary: ON CERTAIN PICKUP TRUCKS, PASSENGER VEHICLES, SPORT UTILITY VEHICLES, AND MOTOR HOMES CHASSIS, THE SPEED CONTROL DEACTIVATION SWITCH MAY, UNDER CERTAIN CONDITIONS, LEAK INTERNALLY AND THEN

OVERHEAT, SMOKE, OR BURN. THIS COULD RESULT IN AN UNDERHOOD FIRE."

1995 Bronco Dealer Brochure @

1995 Ford Bronco

1995 Bronco Drivetrain, Powertrain Service Manual - Google Drive

The eight Groups found in this manual are:

00 - Service Information

02 - Engine and Transmission Mounting

03 - Engine

05 - Driveline

07 - Transmission

08 - Clutch

09 - Exhaust System

10 - Fuel System

Each Section covers a component or system. The second set of numbers on each page

indicates the Section.

If the vehicle has more than one type of component, such as two types of engines or power

steering systems, alphabetical suffixes are used.

&

1995 Bronco Chassis, Service Manual - Google Drive

To switch between folder list & grid views, click the button to the right of the "DOWNLOAD ALL" button in the upper right corner of the window) by HawkDriver

The twelve Groups found in this manual are:

00 - Service Information

01 - Body

02 - Frame and Mounting (Body)

04 - Suspension

06 - Brake System

11 - Steering System

12 - C,imate Control System

13 - Instrumentation and Warning Systems

14 - Battery and Charging System

15 - Audio Systems

17 - Lighting

18 - Electrical Distribution

Each Section covers a component or system. The second set of numbers on each page

indicates the section.

If the vehicle has more than one type of component, such as two types of engines or power

steering systems, alphabetical suffixes are used.

Haynes Red Manual for 80-95 Bronco & F Series @

Hanes guide 80-96 bko f series.pdf via BroncMom!

Al