Whipsaw

New member

- Joined

- Nov 26, 2016

- Messages

- 26

- Reaction score

- 21

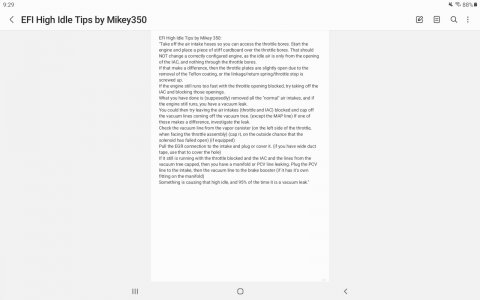

Hi Everyone, its been a while since I've posted here. In the interim, with a new PCM installed, the Bronco has been running well. I do have a problem with high idle when it's warm out ( I think it's a vacuum leak, but I haven't looked that hard yet - if it's the plenum gasket, I'll get to that at some point. I have a replacement vacuum canister (coffee can), the old one is a little rusty, but I don't think its leaking. Turning off the engine and starting again fixes it for a time - if that might indicate what the problem could be). I did have it painted, stock emerald green, got it back from the body shop a few months ago - rust repaired, new front springs installed, new tailgate, new back glass. Looks great! I'll have to get a picture up soon.

The water pump seal just went (need to verify, coolant was running down the front of the engine, could be a cracked hose), if the pump is shot, will be replacing the timing set while I'm in there. After that is an Air Conditioning refit, and probably front wheel bearings.

The water pump seal just went (need to verify, coolant was running down the front of the engine, could be a cracked hose), if the pump is shot, will be replacing the timing set while I'm in there. After that is an Air Conditioning refit, and probably front wheel bearings.