I've searched around the net and have seen this question asked countless times but can not come up with a definitive answer.

I have the common cold start problem where I have to spin the engine long, the engine starts rough and then smooths out quickly and I have done some testing with a fuel pressure gauge. The pump makes 40psi KOEO. The regulator limits the pressure to ~32psi idling. When I turn the engine off the pressure holds up for a long time. I think that it was a half hour before it dropped at all. The pressure goes to zero overnight.

Now I have seen claims that it is normal for pressure to drop to 15 - 20 psi 15 minutes after stopping engine. I have also read that it is normal if the pressure is zero after sitting overnight and some that claim that it should hold pressure overnight. I plan to do further testing by clamping off the feed and return fuel lines overnight both together and individually but in the meantime.....

My first question:

1 Is it normal for the fuel pressure to drop to zero after sitting for 12 hours or so?

and

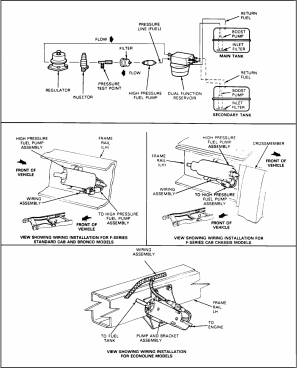

2 Where are the check valves in the fuel system?I have seen claims that they are in the fuel tank pump and in the high pressure pump and in the regulator and in the reservoir. The best that I can tell so far is that there are two in the single function reservoir, one in each direction, and I can't seem to veriy that for sure.

EDIT

I am aware that the pressure escapes through three possible routes, the supply line, the return line and the injectors. There is no black smoke when the engine starts and the problem only occurs after the car has sit for an hour or more.

I have the common cold start problem where I have to spin the engine long, the engine starts rough and then smooths out quickly and I have done some testing with a fuel pressure gauge. The pump makes 40psi KOEO. The regulator limits the pressure to ~32psi idling. When I turn the engine off the pressure holds up for a long time. I think that it was a half hour before it dropped at all. The pressure goes to zero overnight.

Now I have seen claims that it is normal for pressure to drop to 15 - 20 psi 15 minutes after stopping engine. I have also read that it is normal if the pressure is zero after sitting overnight and some that claim that it should hold pressure overnight. I plan to do further testing by clamping off the feed and return fuel lines overnight both together and individually but in the meantime.....

My first question:

1 Is it normal for the fuel pressure to drop to zero after sitting for 12 hours or so?

and

2 Where are the check valves in the fuel system?I have seen claims that they are in the fuel tank pump and in the high pressure pump and in the regulator and in the reservoir. The best that I can tell so far is that there are two in the single function reservoir, one in each direction, and I can't seem to veriy that for sure.

EDIT

I am aware that the pressure escapes through three possible routes, the supply line, the return line and the injectors. There is no black smoke when the engine starts and the problem only occurs after the car has sit for an hour or more.

Last edited: